A spring balancer or balancer is an indispensable component for the ergonomic design of commercial workstations in industry. transprotec GmbH offers a wide range of spring balancers and balancers in standard and ATEX-certified versions for hazardous areas. Depending on the model, the rope lengths of these devices vary between 1,200 mm and 3,000 mm and therefore offer flexible solutions for different requirements.

Balancer 16940(..), 16941(..), 16942(..)

Show product

Balancer with 167230(..), 167231(..)

Show product

Balancer SWF, short rope

Show product

Spring balancer 1093(..) with locking device

Spring balancer 16935(..)

Show product

Balancer 16943(..), 16944(..), 16945(..)

Show product

Balancer with 167235(..), 167236(..)

Show product

Spring balancer 16936(..), 16937(..)

Show product

Balancer with EX protection 16935(..)ex

Show product

Balancer SWF-L, long cable

Show product

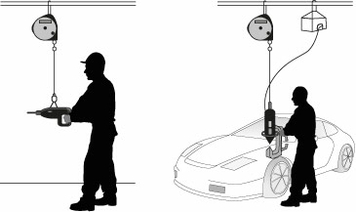

Spring balancers and balancers are mainly used in the design of industrial workstations, taking ergonomic requirements into account.

It should be noted that spring balancers and balancers do not belong to the hoist family. This means that load changes, e.g. by hanging and unhooking loads, are not permitted.

Spring balancers are mainly used to hold tools such as electric screwdrivers at industrial workstations and to guide cable assemblies at fully automated production stations such as robot workstations. The devices are used to make work easier and to increase workplace safety and productivity. Due to the tensile forces to be applied, spring balancers have load capacities of up to 14 kg, depending on the device. The cable guide is realized with the aid of spirally wound cable drums and spiral springs and the necessary tensile force is built up by tensioning the spiral spring. Due to the rope drum shape in conjunction with the spiral spring, the retraction force increases with increasing rope extension. This design ensures that the rope is wound up when the load is released, provided that the load capacity specifications of the respective devices are implemented in accordance with the operating instructions.

Depending on the device type, it is optionally possible to obtain spring balancers with a locking function. By using devices with a locking function, it is possible to position the suspended load at the desired height. Spring balancers without locking functions automatically pull the suspended load back to its original position after use. The possible uses of spring balancers and balancers are very similar. Both types of device are used to hold tools. In contrast to spring balancers with load capacities of up to 14 kg, balancers can, depending on the design, achieve load capacities of up to 200 kg. The key design difference between spring balancers and balancers is the design of the rope drum.

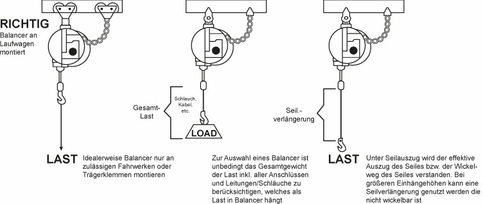

While the rope drums of spring balancers are designed for spiral winding and the rope is laid on the drum layer by layer, the rope drums of balancers are conical in shape. The rope is wound onto a grooved drum side by side with increasing diameter, resulting in optimum weight balance.

The resulting torque increases as the tension of the coil spring increases, which is due to the degree to which the cable is pulled out and the resulting force. The retraction force increases as the rope is pulled out and the spring force is increased at the same time. The rope radius on the rope drum theoretically remains constant, although it should be noted that, depending on the type, the ropes are spirally wound and therefore a slight change in the radii is possible. If the rope is released, the winding process is initiated by the spring force, whereby the weight force G is eliminated.

Like spring balancers, balancers are also indispensable for the design of workstations with higher loads. Like spring balancers, balancers increase work safety, facilitate work processes and help to increase productivity. They provide considerable physical relief for your colleagues and employees and are sometimes indispensable for the implementation of work processes. While spring balancers cover load capacities of up to 14 kg, balancers can accommodate loads of up to 200 kg, depending on the design. Balancers are sometimes also referred to colloquially as weight balancers or rope balancers. The term “weight balancer”, along with the term “balancer”, refers to the most important feature of this type of device. The balance function or weight equalization function is implemented by the conically shaped, grooved rope drums in conjunction with a spiral spring or a spiral spring assembly. The combination of the conical drum shape in conjunction with the spiral spring ensures an almost constant tensile force. Balancers are always designed with a steel cable. The cable lengths can vary depending on the type of device. The weight range of the balancer can be adjusted to the desired load using an adjusting screw, whereby it should be noted that the balancer load capacity is defined by a minimum and maximum weight specification. Each device has an adjustment range of several kilograms. The correct setting is achieved when the suspended load can be held in a suspended state, regardless of the length of the cable extension.

As with the spring balancer, the spring is also pre-tensioned, which means that both an initial torque and a retraction force must be taken into account. Both the spring tension and therefore the torque increase with the increase in rope extension. In order to be able to balance the weight of a balancer, the rope drum is conical (variable load lever), which means that the increase in torque and the resulting increase in retraction force are balanced out.

Example:

Exceeding the load range:

The weight of the suspended load is greater than the load-bearing range of the spring balancer or balancer. The load sags and the balancer or spring balancer cannot compensate for the load or pull it back, contrary to its function.

Falling below the load-bearing range:

If the load-bearing range of a spring balancer is undercut, the user must apply considerably more force to pull the load suspended in the spring balancer downwards. There is also an increased risk of injury if the rope is wound up very quickly. If the load range of a balancer is undercut, the desired effect of weight compensation cannot be achieved. As with the spring balancer, there is also an increased risk of injury to the user if the load range is undershot as a result of uncontrolled winding of the rope. Furthermore, falling below the permissible load range can lead to considerable damage to the balancer, e.g. by skipping grooves in the rope on the conically grooved rope drum.

Do you have any questions about spring balancers and balancers? We will be happy to help you choose the right device. Our experts are on hand with help and advice.

We are able to cover the complete range of services from planning, calculation, manufacture, installation and commissioning. Please get in touch with us:

Phone: +4940 870 859 78 0

E-Mail: info@transprotec.de

A spring balancer improves ergonomics and productivity at industrial workstations by making work processes easier. By automatically returning the tools to their starting position and adjusting the pulling force according to the cable extension length, the spring balancer relieves the physical strain on employees. This leads to a reduction in fatigue and an increase in work efficiency.

The use of spring balancers increases the longevity of work processes, as these devices are specially designed for industrial use and have a high load capacity. The robust design and reliable function of the spiral springs and rope drums ensure that tools can be handled safely and efficiently. This reduces wear and tear on tools and machines and leads to a sustainable investment in workplace quality.

The spring balancer is indispensable for the ergonomic design of workstations because it offers considerable physical relief for employees by automatically returning the tools and adjusting the pulling force. The ability to position the load at the desired height without having to make constant manual adjustments reduces the risk of musculoskeletal complaints and therefore increases workplace safety and employee well-being.