Electric wire rope winch ETSW-ST

Mobile electric cable winch

Show product

Electric cable winch LA-B300

Show product

TAPW electric cable winch (up to 10 t)

An electric cable winch from transprotec: compact, robust, flexible and durable. Our various models are designed for material transport and can be configured as hoisting winches or pulling winches. Regardless of whether you require 230 V or 400 V, want to move 250 kg or 100 tons, are planning mobile use or a fixed part of your system. Our tailor-made solutions reliably guarantee maximum performance in demanding industrial environments.

Let us advise you individually now!

Electric wire rope winches are classified into different drive unit groups depending on the planned mode of operation, running times and load requirements. The average running time/day over an entire calendar year (running time class) and the frequency of the full load or the relative load level must be used as the basis for the determination. The stresses resulting from this analysis are the basis for dimensioning an electric wire rope winch (DIN15020, ISO 4301/1, FEM 1.001; FEM9.511).

| ISO (FEM) | Operations per hour | Theoretical usage D | Power-on time |

| M3 (1Bm) | 150 | 400 h | 25% ED |

| M4 (1Am) | 180 | 800 h | 30% ED |

| M5 (2m) | 240 | 1.600 h | 40% ED |

| M6 (3m) | 300 | 3.200 h | 50% ED |

| M7 (4m) | 360 | 6.300 h | 60% ED |

We manufacture electric wire rope winches

The options available for many of the models include

Special design

Electric cable winch with lift truck

Contactor control:

Contactor controls only allow one winding speed for winding and unwinding. In the standard version, all electric wire rope winches are equipped with a contactor control. The use of a contactor control is a prerequisite for equipping the cable winch with limit switches, which are required for hoisting cable winches.

Frequency inverter control:

Depending on the application, customer requirements or the pulling or lifting force, the use of frequency converter controls is required. An electric wire rope winch can be designed with at least two winding speeds using the frequency inverter control. If a potentiometer is also used, infinitely variable control of the winding speeds is possible. For large or sensitive loads, a starting time and braking time can be programmed using the frequency inverter control.

Grooved rope drum:

Initially, all cable winches are designed with a smooth cable drum as standard. Depending on the type of application or the distance to the first deflection pulley, it makes sense to use a grooved rope drum. It not only improves the winding behavior of the rope, but also significantly increases the service life of the steel wire ropes. The use of grooved rope drums in conjunction with textile ropes must be checked and decided on a case-by-case basis.

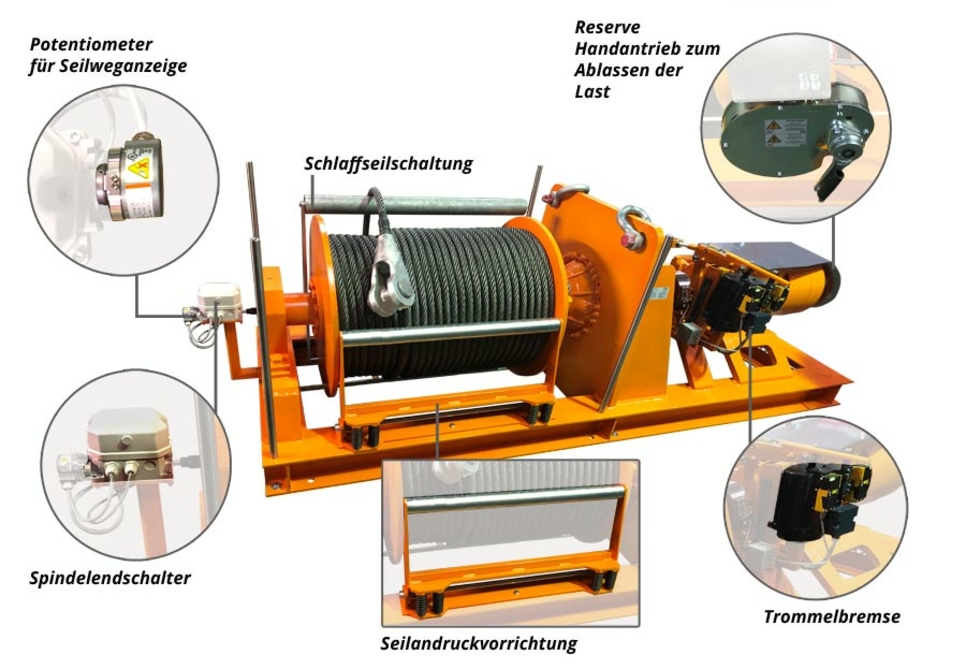

Rope pressure device:

Rope pressure devices are provided exclusively in conjunction with the use of a grooved rope drum. Their task is to press an unloaded rope into the rope groove or previously wound rope layer. The rope pressure device optimizes the winding behaviour of the rope while at the same time reducing rope wear.

Overrunning clutch:

Electric rope winches with freewheel clutches are only permitted for use on pulling winches, i.e. for pulling loads horizontally. Overrunning clutches allow the rope drum to be decoupled from the drive unit, e.g. to enable the rope to be unwound manually.

Drum protection cover:

Drum protection covers on motorized cable winches are required to prevent reaching into the rotating cable drum.

We offer you the necessary periodic inspections (UVV) for your cable winches.

Every electric cable winch must be inspected at least once a year.

Limit switch:

Limit switches must be used to prevent the load hook from exceeding the design or desired limits. This applies to all electric wire rope winches, regardless of whether they are hoisting or pulling winches. Motorized hoisting winches must be equipped with limit switches. Electric wire rope winches are usually equipped with spindle limit switches. As a rule, the spindle limit switches are installed in the extension of the drum axis. They define the winding path and limit it by setting the respective cam switches.

Slack rope switch:

The slack rope switch is intended to enable the electric rope winch to be switched off immediately if the rope is not wound tightly onto the rope drum. This can occur with both towing winches and hoisting winches if the cable pulling force is no longer sufficient. The slack rope switch thus prevents the rope from looping on the rope drum of the electric cable winch.

Handbrake release:

In order to be able to lower the load manually in the event of a power supply failure, there is the option of equipping the cable winches with a hand brake release, depending on the design.

Reserve manual drive:

If there is a system standstill on an electric winch due to a power failure, it is possible to lower the load safely using the reserve manual drive.

Drum brake:

The drum brake can be used as an additional braking system on electric wire rope winches. The drum brake acts directly on the drum and can be opened or closed manually.

Rope travel indicator:

The rope travel indicator on an electric cable winch provides information on the unwound or still drummed rope length on the rope drum. For multi-layer windings, please state this explicitly in your inquiry!

Electric cable winches must be checked regularly to ensure that they are working properly and do not pose a risk to people. There are different types of cable winches with different testing requirements.

We offer you the necessary periodic inspections (UVV) for your cable winches.

Every electric cable winch must be inspected at least once a year.

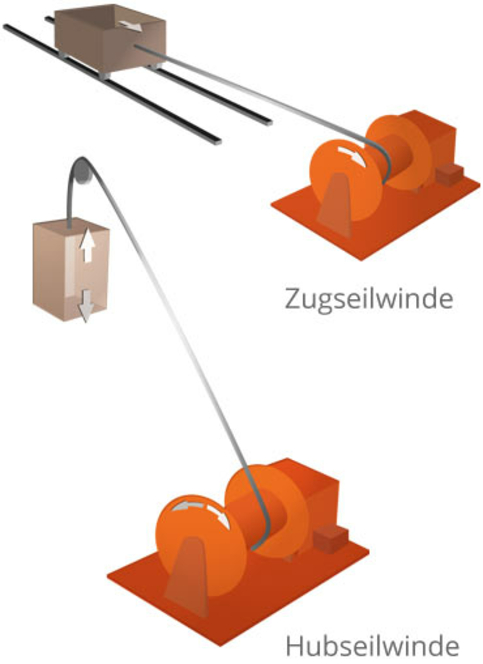

In order to comply with the applicable requirements of the Machinery Directive, a fundamental distinction must first be made when designing an electric wire rope winch:

Pulling winch or lifting winch

According to the Machinery Directive, pulling loads along an incline (greater than 10°) is already considered a lifting operation and requires a hoisting winch. Based on this definition, it is clear which accessories are permissible for the design and subsequent use of the electric winch.

Note:

A designated pulling winch

is supplied with a declaration of incorporation and may not initially be used as a hoisting winch

A designated hoisting winch

is supplied with a declaration of conformity. These may be used both as a lifting winch and as a towing winch.

To help you find the right electric wire rope winch, transprotec's technical consultants will be happy to arrange a personal consultation.

Phone: +494102 7789-600

E-Mail: info@transprotec.de

The environment in which an electric wire rope winch is used plays a decisive role. For example, special non-sparking motors are required for the ATEX area. For offshore applications, for example, special paintwork is used for corrosion protection. And when used indoors, special requirements may also be placed on the paint and motor due to high temperatures (industrial ovens), for example.

Electric wire rope winches are versatile and can be used for horizontal pulling and lifting of loads, especially for high lifting heights or heavy loads, and run more quietly and with less wear than chain hoists. Electric chain hoists, on the other hand, are only suitable for lifting and scoring due to their compact, mobile design.

Electric wire rope winches from transprotec, manufactured in Germany, offer numerous advantages for material handling in industrial environments: they are compact, robust, flexible and durable. With models for loads from 250 kg to 100 tons, for 230 V or 400 V, they meet a wide range of application requirements, whether mobile or as a fixed system component, and guarantee maximum performance under demanding conditions.

Pulling winches are used for the horizontal pulling of loads. Hoisting winches are used for the inclined pulling of loads (e.g. slipping boats) through to the vertical lifting of loads. It is irrelevant in the classification whether deflection pulleys are used. The consideration relates to the movement of the loads. Hoisting winches must be able to hold the suspended load permanently in the event of a power failure. More info

The requirement depends on the load to be pulled or lifted. For pulling winches, the load must be multiplied by the rolling resistance. Background: On harder and smooth surfaces (steel on steel), for example, the expected rolling friction is lower than on soft and rough surfaces (car tires on asphalt).

In principle, higher safety factors apply to the transportation of people than to the transportation of materials. Our electric wire rope winches are designed for transporting materials.

There are two remote control options:

1. electric wire rope winch with radio remote control

The range of the radio remote control to the radio receiver on the electric wire rope winch can be up to 100 m under ideal conditions.

The radio receiver is plugged into the electric cable winch. Retrofitting is only possible with relatively high control engineering effort.

2. electric wire rope winch with wired remote control

With the wired remote control, there is a hard-wired connection or a plug-in system.

With the remote control with plug-in system, different operating lengths can easily be realized and it is easy to maintain.

Another advantage: more attractively priced than radio remote controls.

Cable winches can be equipped with only one, several (e.g. coarse and fine hoist) or with infinitely variable winding speed. Example values for simple speeds 4 m/min, 8 m/min, 12 m/min etc.

The winding path of your electric wire rope winch is the distance that your load travels. The rope length may deviate from the winding path as more rope is required due to additional deflection pulleys and rope guides.

As a rule, all cable winches for material transport are designed with steel cables. Steel ropes are characterized by their ability to absorb dynamic forces and their high breaking strength and tensile strength. In addition, very good winding behavior can be achieved with steel ropes. Disadvantage: high weight.

Synthetic ropes (e.g. Dyneema ropes) are characterized by their low weight. The major disadvantage of using a synthetic rope on electric winches is the poor winding behavior. Particularly with long rope lengths and when winding several layers, the winding behavior can only be controlled with comparatively great technical effort.

When using steel wire ropes, a distinction is made between rotation-resistant and non-rotation-resistant ropes (DIN EN 12385)

Low-rotation rope:

Electric wire rope winches with low-rotation ropes can be used as hoisting winches with which a freely suspended (unmoved) load can be lifted. The rope rotates only slightly along its longitudinal axis.

Non-rotation-resistant rope:

Non-rotation-resistant ropes are used in an electric wire rope winch when the load is guided using rails, for example.

The employers' liability insurance association distinguishes between 3 scenarios here:

We can design your electric wire rope winch for all 3 scenarios.