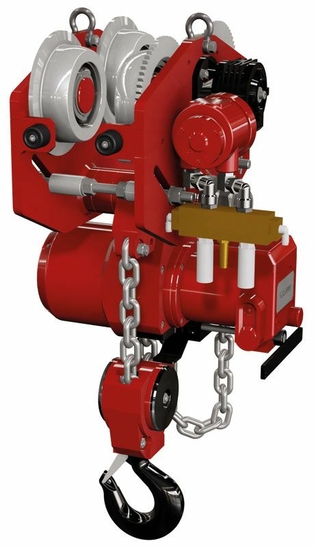

Pneumatic chain hoist TCR-250ME

Pneumatic chain hoists & trolleysTCR, TNC

Show product

Robust pneumatic chain hoist for heavy-duty industrial applications:The TCR, RRI and TCRM series

An air chain hoist from the TCR, RRI and TCRM series can generally be used wherever electric chain hoists are used. Thanks to their extremely robust design, TCR, RRI and TCRM air chain hoists are suitable for continuous operation in heavy-duty industrial applications. Thanks to this design (high-strength cast steel housing, permanently lubricated planetary gearbox), maintenance costs / maintenance times are very low. Operation is very simple, each air chain hoist can be supplied with a rope control or a chain control. Regardless of the type of control, the devices are characterized by smooth start and stop operation as well as variable lifting and lowering speeds, which is essential for precise positioning.

In addition to use in corrosive environments, the TCR series air chain hoist is also suitable for use in potentially explosive atmospheres (hazardous areas up to zones 2 and 22, II B, T4) thanks to its spark-proof and robust motors.

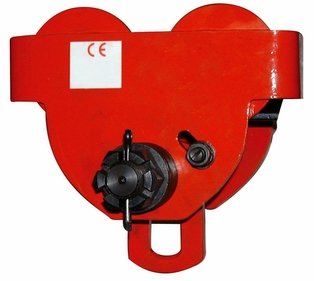

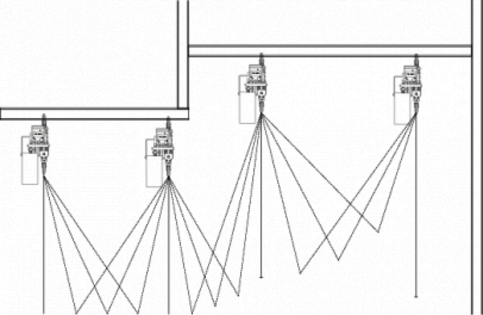

We also offer a range of special trolleys. Thanks to our many years of experience, tailor-made, customer-specific solutions and designs are available on request at any time.

Features of the pneumatic chain hoist

Compared to traditional electric or hydraulic lifting systems, air chain hoists offer improved energy utilization and support efficient operations. The use of compressed air as a drive medium optimizes the use of energy and can lead to reduced energy requirements in certain configurations. In addition, air chain hoists minimize the risk of malfunctions that can occur with other systems due to oil leaks. These features mean that our chain hoists promote smooth and low-maintenance operation, making them a valuable solution for lifting and positioning loads in industry.

Like all hoists, the transprotec air chain hoist is designed for vertical lifting.

Under certain circumstances, it is possible to pull loads at an angle with a single or double fall pneumatic chain hoist. The angle from the vertical should not exceed 20°

It is essential to take special precautions for inclined pulling:

A site assessment should be carried out:

1. Power source and infrastructure:

Pneumatic chain hoists require a compressed air supply, which assumes the presence of suitable infrastructure.

In facilities with a central compressed air system, this is typically not an issue. However, in other environments, the installation can be more costly compared to electric systems.

2. Cost and cost-efficiency:

Initial investment costs for pneumatic hoists are often higher, but they can be more cost-effective over time — especially in demanding applications — due to their low maintenance requirements and long service life.

3. Duty cycle and operational demands:

Pneumatic hoists are designed for continuous operation under load and are less prone to overheating than electric models.

This makes them particularly well-suited for frequent, heavy-duty lifting tasks, such as those found in multi-shift operations.

The choice between a pneumatic and an electric chain hoist largely depends on the specific requirements of your application.

Here’s a brief comparison of the key differences:

| Druckluftkettenzug | Electric Chain Hoist | |

|---|---|---|

| Power Source | Requires compressed air supply | Requires electrical power |

| Cost | Higher initial investment, but cost-effective in the long run for continuous use | Lower initial cost, ideal for occasional use |

| Duty Cycle | Suitable for continuous operation – no overheating | Limited duty cycle depending on the model |

| Maintenance | Fewer wear-prone components – low maintenance | More moving parts – may require more regular servicing |

| Noise Emissions | Typically noisier |

Advice and price enquiry

To help you find the right air chain hoist, transprotec's technical consultants will be happy to provide you with personal advice.

Phone: +494102 7789-600

E-Mail: info@transprotec.de

DOWNLOADS

A pneumatic chain hoist (air-powered chain hoist) is an industrial lifting device designed for the safe and powerful lifting, lowering, and positioning of heavy loads. Pneumatic chain hoists are powered by compressed air and are commonly used in industrial applications, especially in environments with high humidity, dust exposure, or in explosion-hazard zones (ATEX).

Compared to electric systems, pneumatic chain hoists are highly energy - efficient, durable, and virtually maintenance-free — making them ideal for reliable continuous operation.

An air chain hoist enables very precise positioning of loads thanks to infinitely variable speeds and the avoidance of jerky movements. This feature is particularly important in applications where precise positioning and sensitive handling are required, such as in assembly lines or during maintenance in power plants. The smooth control supports efficient work processes and increases safety during lifting operations.

Why is an air chain hoist suitable for continuous operation?

Air chain hoists offer a wide range of load capacities, from 125 kg to an impressive 100 tons, making them extremely versatile. They are used in a variety of industrial sectors such as foundries, power plants, assembly lines in mechanical engineering, shipyards, as well as in corrosive or potentially explosive environments. This wide range of applications underlines their robustness and adaptability to a wide variety of requirements and working conditions.