The robust yet compact electric wire rope winch from the MC-E series is particularly suitable for pulling loads in a horizontal direction. It is equipped with a self-locking worm gear which acts as a holding brake. Due to its design features, the MC electric wire rope winch can be installed in all installation positions. The motor is designed as a brake motor for raising/lowering loads or on inclined surfaces in order to safely brake the loads to be lowered.

Basic equipment of the electric wire rope winch:

Options - Control unit:

Options - Mechanics:

Configuration: The MC electric wire rope winches with basic equipment are not yet ready for operation in this condition. A wide range of options allows you to equip the electric wire rope winch with additional equipment specifically for your particular application. The winch can be equipped with a control system, e.g. a contactor control with control box with operating buttons in the cover or a pendant control. All MC-E series winches equipped with a contactor control have an overload protection in the control box and an emergency stop button on the pendant control and/or on the control box.

Scope of delivery in the complete version: The scope of delivery in the complete version includes the electric wire rope winch with brake motor, a 24 V control box with pushbuttons and emergency stop as well as a 3 m connection cable with plug. As an option, you have the option of ordering a rope tailored to your application.

| Electric cable winch type (230 volt) MC-E ... SPH | 250 | 500 | 750 |

| Max. Tensile force 1st rope layer (daN) | 250 | 500 | 700 |

| Max. Tensile force 5th rope layer (daN) | 170 | 340 | 460 |

| Max. Lifting force 1st rope layer (kg) | 200 | 400 | 550 |

| Max. Lifting force 5th rope layer (kg) | 135 | 275 | 360 |

| Recommended rope diameter (mm) | 6 | 6 | 7 |

| Speed 1st rope layer (m/min) | 5 | 5 | 5 |

| Rope take-up 1st rope layer (m) | 2 | 2 | 6 |

| Rope take-up 5th rope layer (m) | 19 | 19 | 42 |

| Motor power 1-Ph/230 V (S2) (kW) | 0,75 | 1,5 | 1,8 |

| Weight without rope and accessories (kg) | 22 | 35 | 55 |

| Electric cable winch type (400 volt) MC-E | 250 | 500 | 750 | 1200 | 1700 | 2200 |

| Max. Tensile force 1st rope layer (daN) | 250 | 500 | 750 | 1200 | 1700 | 2200 |

| Max. Tensile force 5th rope layer (daN) | 170 | 340 | 490 | 750 | 1055 | 1365 |

| Max. Lifting force 1st rope layer (kg) | 200 | 400 | 600 | 960 | 1300 | 1700 |

| Max. Lifting force 5th rope layer (kg) | 135 | 275 | 390 | 600 | 805 | 1055 |

| Recommended rope diameter (mm) | 6 | 6 | 7 | 8 | 10 | 12 |

| Speed 1st rope layer (m/min) | 6 | 6 | 6 | 5 | 6 | 7 |

| Rope take-up 1st rope layer (m) | 2 | 2 | 6 | 5 | 7 | 9 |

| Rope take-up 5th rope layer (m) | 19 | 19 | 42 | 38 | 50 | 63 |

| Motor power 1-Ph/400 V (S2) (kW) | 0,75 | 1,1 | 1,5 | 2,2 | 4 | 5,5 |

| Weight without rope and accessories (kg) | 22 | 35 | 55 | 92 | 140 | 180 |

| Dimensions (mm) | ||||||

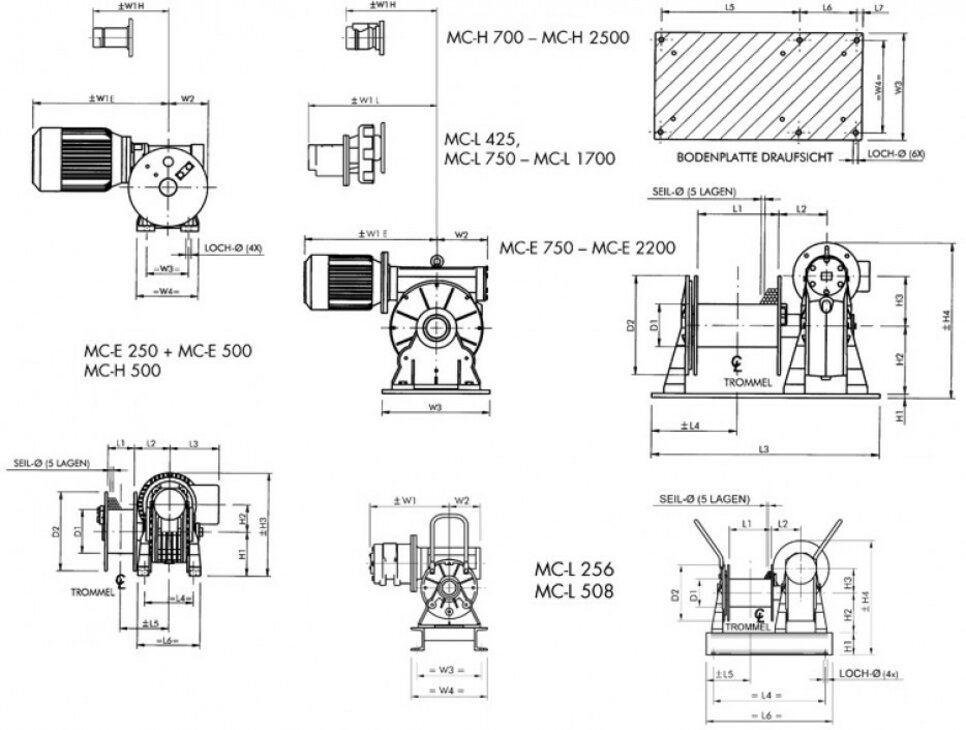

| MC-E electric cable winch | 250 | 500 | 750 | 1200 | 1700 | 2200 |

| Weight (kg) | 20 | 35 | 55 | 92 | 140 | 180 |

| D1 | 100 | 100 | 100 | 100 | 121 | 146 |

| D2 | 180 | 200 | 200 | 250 | 280 | 320 |

| L1 | 60 | 60 | 150 | 150 | 200 | 250 |

| L2 | 81 | 91 | 104 | 125,5 | 146,5 | 155 |

| L3 | 118 | 129 | 500 | 560 | 640 | 710 |

| L4 | 111 | 146 | 187 | 203 | 232 | 260 |

| L5 | 111 | 121 | 320 | 340 | 415 | 470 |

| L6 | 143 | 186 | 150 | 180 | 185 | 200 |

| L7 | - | - | 15 | 20 | 20 | 20 |

| H1 | 100 | 142 | 10 | 10 | 15 | 15 |

| H2 | 62 | 87 | 142 | 170 | 195 | 220 |

| H3 | 233 | 309 | 87 | 110 | 130 | 150 |

| H4 | - | - | 320 | 380 | 443 | 510 |

| W1E | 310 | 358 | 358 | 421 | 492 | 519 |

| W2 | 90 | 110 | 110 | 140 | 154 | 180 |

| W3 | 95 | 140 | 270 | 325 | 370 | 410 |

| W4 | 140 | 220 | 240 | 285 | 320 | 360 |

| Hole Ø | 11,5 | 11,5 | 13 | 17 | 17 | 17 |

You have questions about our products or would like a quote for a specific product? Receive your personal offer quickly and directly.