Balancers are generally indispensable for the design of workstations and can cover a load range of up to 200 kg. They facilitate work procedures and work processes and thus provide enormous physical relief as well as a high level of safety for your colleagues and employees.

Counterbalancers are used to hold tools, whereby the weight of the tool appears almost weightless to the user. Compared to a spring balancer, these devices have a conical cable drum. An almost constant pulling force is guaranteed by the design of the cable drum in combination with the built-in spiral spring.

Balancer 16940(..), 16941(..), 16942(..)

Balancer with EX protection 1695(..)ex

Balancers are generally indispensable for the design of workstations and can cover a load range of up to 200 kg. They facilitate work procedures and work processes and thus provide enormous physical relief as well as a high level of safety for your colleagues and employees.

Counterbalancers are used to hold tools, whereby the weight of the tool appears almost weightless to the user. Compared to a spring balancer, these devices have a conical cable drum. An almost constant pulling force is guaranteed by the design of the cable drum in combination with the built-in spiral spring.

A weight balancer is always supplied with a steel cable, optionally in different cable lengths. Each device has an adjustment range of several kilograms - it can be adjusted to the weight of the tool to be suspended with the aid of an adjusting screw in order to achieve an optimum floating state of the tool.

The exact specification of the tool weight and the required cable extension is crucial for optimum use. In addition to the devices described, a distinction is made between weight compensators with a locking mechanism. The locking mechanism only engages when the working load is slowly retracted. The automatic locking mechanism can be deactivated by pulling back quickly. Alternatively, the locking mechanism can also be operated using an optional pull chain. The weight balancer housings are made of impact-resistant plastic or cast aluminum.

The casing of the balancer is made of die-cast aluminum.

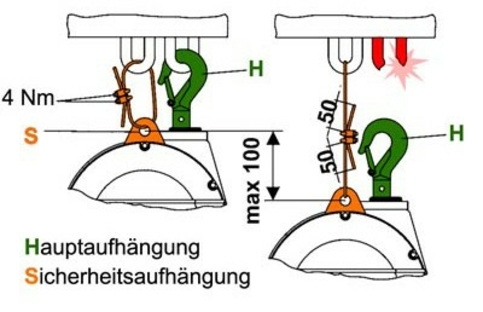

A) Rear housing section with safety suspension

D) Front with appliance safety hook (main suspension)

E) Gehäuse-Flanschring

There are 2 groups of components inside the balancer:

B) Cable drum

The cable drum spring assembly is supplied fully assembled.

The spring is permanently lubricated in the drum and must NOT be pulled out.

C) Rope with spring stop and carabiner holder

The balancer must be inspected at least once a year by authorized specialist personnel, supplemented by regular visual inspections (e.g. once per work shift).

Maintenance work may only be carried out by authorized specialist personnel

We will be happy to help you choose the right balancer. Our experts are on hand with help and advice.

We are able to cover the complete range of services from planning, calculation, manufacture, installation and commissioning. Please get in touch with us:

Phone: +4940 870 859 78 0

E-Mail: info@transprotec.de

A balancer, also known as a weight compensator or positioner, is a technical device that is used to support and simplify various work processes.

The balancer is used to compensate for the weight of a tool or load, enabling almost weightless operation.

Balancers are used in various areas and working environments.

For example, they are often used in industrial production to handle heavy tools or components.

They are also used in assembly processes to position components in the air and provide workers with an ergonomic working position.